LANDFILL

GAS-TO-ENERGY TREATMENT PLANTS

Landfills produce large amounts of greenhouse gases every year and when left uncollected, these gases are devastating to the environment, climate, and earth as a whole. For landfill owners, the required flaring of these harmful gases often demands capital outlay, while providing absolutely no return on investment once LFG is eliminated. When LFG is properly treated, it can be repurposed as a profitable, long-term source of renewable energy and reduce compliance risk for landfills.

HIGH-BTU LFG

If LFG is treated to high-BTU specifications, it consists of about 95% or greater methane, 1-3% nitrogen and 1-2% carbon dioxide. All contaminants and volatile organic compounds (VOCs) have been removed and incinerated. From there, the gas can be sold into a natural gas pipeline, offsetting the world’s shrinking fossil fuel reserves, while almost completely eliminating the environmental consequences of solid waste decomposition.

LFG-TO-PIPELINE

Instead of maintaining and operating equipment to flare LFG, a few different procedures make it possible to harness the energy potential of landfill gas for profit: electric power generation, development of medium-BTU industrial fuels, and injection of high-BTU gas into utility company pipelines.

We believe the LFG-to-pipeline production model is the best solution for most landfills managing 150,000 tons of waste or more each year, particularly in areas where the difference between the cost of fuel to produce electricity and the price of that same unit of electricity (known as the spark spread) is considered low. A high-BTU gas project is likely more viable in these areas than a power plant.

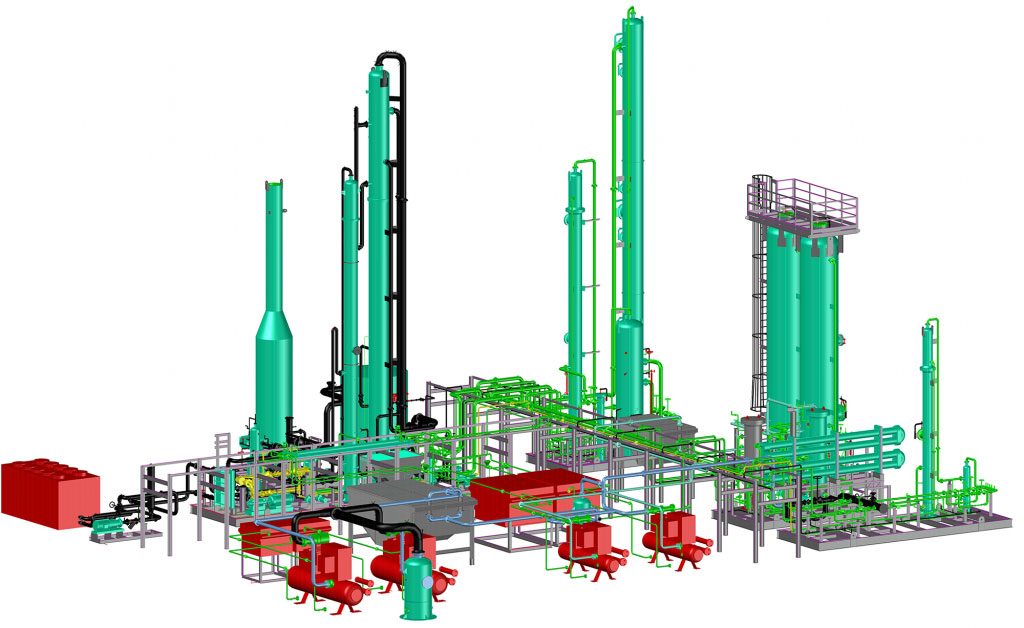

Morrow Renewables advantages over other high-BTU options:

- Physical solvent (Selexol/AGR) is highly tolerant of volume swings.

- Morrow Renewables can construct a project in less than half the time of other developers, generating revenue more quickly.

- Standard gas treating equipment that is readily available

- Highest methane recovery with limited recycle compression

- Runtime from Morrow Renewables’ facilities average better than 97.5%.

- Lower noise levels and emissions than an electric generation plant build greater community support.

- Negligible air emissions reduce permit requirements. High BTU gas treating actually lowers site emissions when compared to flaring.

- Processed gas can be transported to higher priced Vehicle Fuel markets, offering much better economics to the landfill owner.

- High BTU gas can be moved to any high-value market through the interstate pipeline system.

- Medium-BTU projects are based on a discount to the natural gas market, which is trading at historically low levels. Medium-BTU projects also require a 24/7 gas user nearby to work.

- High-BTU projects capture value from three distinct markets: natural gas, cellulosic biofuel, and low carbon fuel standard.

- The interstate pipeline system allows high BTU gas to move to several markets, including international renewable markets.

- Physical solvent (Selexol/AGR) is highly tolerant of volume swings.

- Morrow Renewables can construct a project in less than half the time of other developers, generating revenue more quickly.

- Standard gas treating equipment that is readily available

- Highest methane recovery with limited recycle compression

- Runtime from Morrow Renewables’ facilities average better than 97.5%.

- Lower noise levels and emissions than an electric generation plant build greater community support.

- Negligible air emissions reduce permit requirements. High BTU gas treating actually lowers site emissions when compared to flaring.

- Processed gas can be transported to higher priced Vehicle Fuel markets, offering much better economics to the landfill owner.

- High BTU gas can be moved to any high-value market through the interstate pipeline system.

- Medium-BTU projects are based on a discount to the natural gas market, which is trading at historically low levels. Medium-BTU projects also require a 24/7 gas user nearby to work.

- High-BTU projects capture value from three distinct markets: natural gas, cellulosic biofuel, and low carbon fuel standard.

- The interstate pipeline system allows high BTU gas to move to several markets, including international renewable markets.

- Physical solvent (Selexol/AGR) is highly tolerant of volume swings.

- Morrow Renewables can construct a project in less than half the time of other developers, generating revenue more quickly.

- Standard gas treating equipment that is readily available

- Highest methane recovery with limited recycle compression

- Runtime from Morrow Renewables’ facilities average better than 97.5%.